-

Facility and Equipment

Hydro Australia has state of the art facilities all across the Pacific catered to all of your needs. With our faclities servicing pumps from all major manufacturers, on-site assistance, 3D scanner, and engineered spare parts, you'll never have to worry about rotating equipment failure again.

Quality Work Begins with a Quality Shop

Hydro Australia’s is certified to ISO 9001:2022, ISO 45001:2022, OHSAS 18001:2007, AS/NZS 4801

The workshop is purpose-built to cater to the needs of the pump industry.

Equipment including a fully equipped machine shop with the capacity to repair or manufacture most parts required for pump refurbishment and rotating equipment. With many lathes, vertical boring, milling, CNC machining, Hydro Australia can manufacture components of varying sizes.

In addition to machines, the workshop is equipped with 3D laser scanning equipments, two 12-ton overhead cranes, spray painting booth, Schenk computerised balancing machine, pressure testing and a purpose designed and built vertical pump assembly pit.

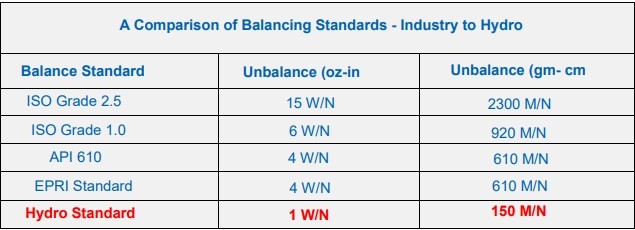

Hydro's Balancing Standards

Hydro Australia balances impellers and rotors in house, up to 4m in length and 3,000kg.

Reverse Engineering - Creaform 3D Scanner and Romer Arms

Whether it be in your facility or ours, we are able to reverse engineer a vast assortment of components using our Creaform 3D Scanner and Romer Arm This scanning creates the basis of reverse engineering and redesigning of components.

Feed pump barrel concentricity and machining on site, in situ

On Site Machining & Welding

Hydro Australia’s on-site field service experience includes:

• Boiler feed and booster pumps

• Auxiliary and main cooling water pumps

• Condensate extraction pumps

• Fire service and balance of pumps

All major manufacturers including Ebara, Ingersoll Rand, TKL, Weir, Hitachi, Mitsubishi, KSB,

Flowserve, Alstom, Aliis Chalmers, K&L, Pacific, Worthington, Jonston, Harland, Klaus Union,

Mather & Platt, Sulzer, Alyne & Bowler, Sumitomo and Voith

-

Wireless Conditioning Monitoring

The majority of our client's pumps are monitored by a monthly check using handheld equipment. Hydro's Centaur Wireless Contditioning Monitoring system uses magnetically attached sensors and a wireless gateway that are continuously monitored, where the data can be accessed 24/7 by client staff and Hydro's Engineers.