- Where required, hydraulic components are tested in Hydro’s Performance Test Lab

- Hydro’s Quality Assurance Team inspects machined component

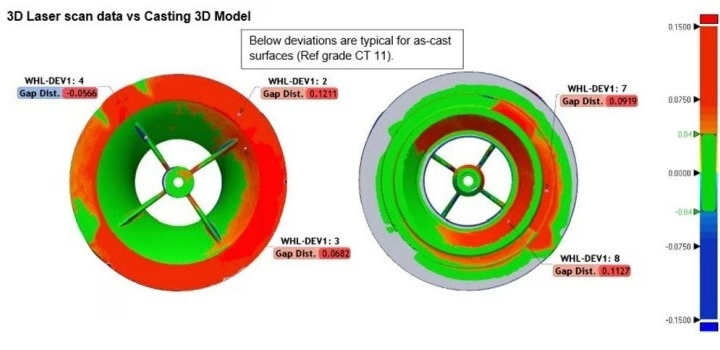

- Equivalency analysis is performed to check adherence to original model dimensions

- After casting approval, final machine drawing is produced and approved

- Machining, drilling, surface finish and dressing is performed

- Casting is inspected for defects

- 3D model of the cast part is created and compared to the original model to validate the casting dimensions before it is released for machining

- High content zircon wash is applied on all surfaces to improve surface finish

- Package is assembled and pour is completed

- Part is poured, broken out of the mold and cleaned

- Cast part is dimensionally inspected by Hydro’s engineers.